Tap images and cards to view more details on the Quality and Product pages

TITAN PIPES is a manufacturer and supplier of high-quality High-Density Polyethylene (HDPE) products, specializing in solutions for industries ranging from construction and agriculture. Founded in 2024, we have established ourselves as a trusted name in the HDPE industry, known for innovation, reliability, and a commitment to sustainability.

At TITAN PIPES, our mission is to provide our customers with the highest-quality HDPE products, manufactured with precision and environmental responsibility. We are dedicated to advancing the use of durable, cost-effective, and eco-friendly materials in a wide range of applications. Our goal is to deliver solutions that meet our customers needs while maintaining the highest standards of safety, quality, and environmental stewardship.

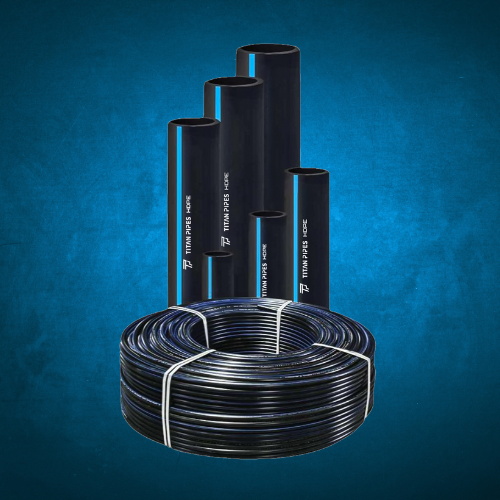

High-Density Polyethylene pipes offering exceptional chemical resistance, flexibility, and durability. Perfect for water supply, gas distribution, and industrial applications. Our HDPE pipes provide long-lasting performance with excellent flow characteristics and resistance to corrosion and environmental stress cracking.

Polyvinyl Chloride pipes known for their strength, lightweight design, and cost-effectiveness. Ideal for plumbing, drainage, and sewage systems. Our PVC pipes offer excellent chemical resistance, easy installation, and long service life with minimal maintenance requirements.